In the realm of modern manufacturing, CNC (Computer Numerical Control) technology stands out as a game-changer, particularly in the field of custom fabrication. As we delve into the profound impact of CNC technology, we’ll explore how it’s reshaping the landscape for custom fabricators in Alabama and beyond.

Understanding CNC Technology: A Digital Transformation

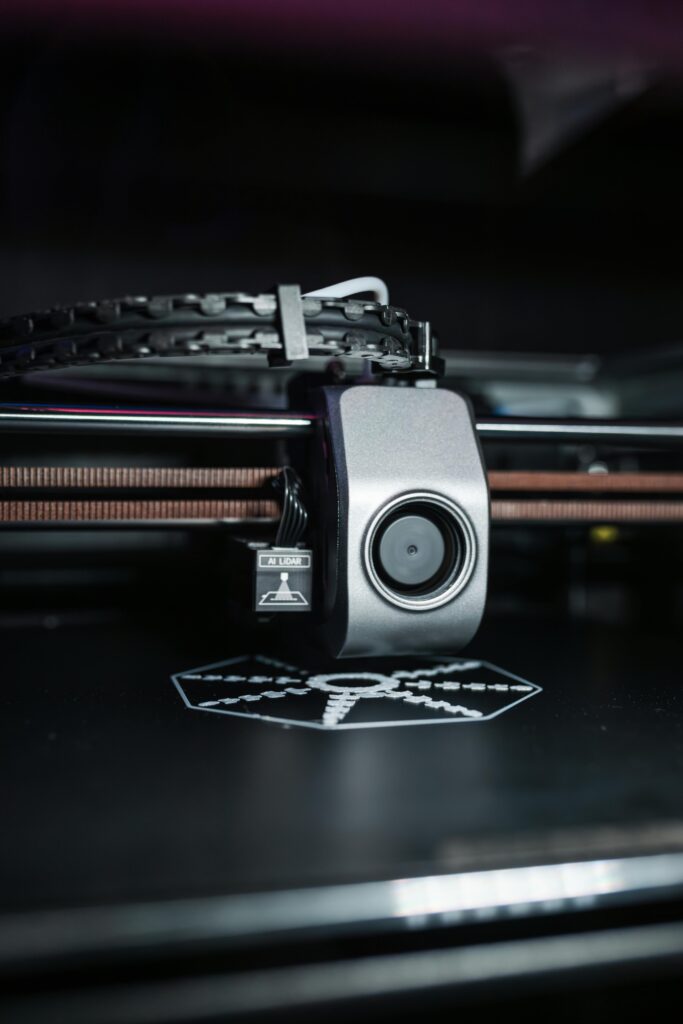

CNC technology represents a significant shift from traditional manual methods to automated precision. At its core, CNC utilizes computer programs to control machinery and tools, allowing for highly precise and complex manufacturing processes. This digital transformation empowers custom fabricators to achieve unparalleled accuracy and efficiency in their production workflows.

Enhancing Precision and Quality

One of the most notable advantages of CNC technology is its ability to deliver unparalleled precision and quality in custom fabrication. By leveraging advanced software and machinery, CNC companies can execute intricate designs with microscopic accuracy, ensuring consistency and reliability across every component. This precision is crucial for meeting the exacting standards of industries ranging from aerospace to automotive.

Streamlining Production Processes

In the competitive landscape of custom fabrication, efficiency is paramount. CNC technology streamlines production processes by automating repetitive tasks and minimizing human error. This not only accelerates manufacturing timelines but also reduces costs associated with labor and material wastage. As a result, custom fabricators can deliver superior products to their clients in a more timely and cost-effective manner.

Flexibility in Design and Innovation

The versatility of CNC technology enables custom fabricators to explore new realms of design and innovation. Unlike traditional manufacturing methods, which may be limited by manual capabilities, CNC machining allows for the realization of intricate and complex geometries. This flexibility empowers designers and engineers to push the boundaries of creativity, resulting in products that are both functional and visually stunning.

Adapting to Evolving Demands

In today’s fast-paced market, agility is key to staying ahead of the curve. CNC technology equips custom fabricators with the agility they need to adapt to evolving demands. Whether it’s adjusting production volumes, revising designs on the fly, or accommodating last-minute changes, CNC machining offers unparalleled flexibility. This agility enables custom fabricators to respond swiftly to shifting market dynamics and emerging opportunities.

Empowering Local Economies

In states like Alabama, where manufacturing plays a vital role in the local economy, the adoption of CNC technology has far-reaching implications. By investing in CNC capabilities, custom fabricators in Alabama can enhance their competitiveness on both a regional and global scale. This not only fosters economic growth and job creation within the state but also strengthens its position as a hub for advanced manufacturing technologies.

Conclusion: Embracing the Future of Custom Fabrication

As we’ve explored, CNC technology is revolutionizing the landscape of custom fabrication in profound ways. From enhancing precision and quality to streamlining production processes and fostering innovation, CNC machining offers a multitude of benefits for custom fabricators. By embracing this technology, companies can position themselves for success in an increasingly competitive marketplace while driving economic growth and innovation in their respective regions.